Cryogenic tanks and doers

Today, according to the various needs in the field of industry, treatment and research for the supply of medical, industrial and laboratory gases, we require compact storage in acceptable volumes. Therefore, the cryogenic industry will be a suitable solution to provide this need.

Cryogenics is a science that deals with the production of gases at very low temperatures. Therefore, in order to maintain and store these gases cryogenically, conditions must be created that can maintain low temperature. Doers are one of the tanks used in this industry, which has a special place due to the following advantages.

dewars

Doers were one of the important inventions for the development of the cryogenic industry in the 19th century, which today is a vital element for storing some common gases. These tanks are actually named in honor of Dewar Games, a chemist and physicist who designed a container (vacuum flask) in 1892 to keep liquid gas cold enough.

The structure of the circles

Doers consist of two internal and external tanks. The inner tank is made of austenitic stainless steel and the outer tank is made of carbon steel. The characteristic of these tanks is that its internal temperature is -196 degrees Celsius and the temperature of its external tank is +50 degrees Celsius. The maintenance of these tanks requires no electricity and energy consumption, and the distance between the layers has a vacuum and consists of insulating materials such as perlite (which significantly reduces the transfer of radiant heat), as a result of this, it causes It becomes a very good insulator for heat.

The advantages of using doers

Doers consist of two internal and external tanks. The inner tank is made of austenitic stainless steel and the outer tank is made of carbon steel. The characteristic of these tanks is that its internal temperature is -196 degrees Celsius and the temperature of its external tank is +50 degrees Celsius. The maintenance of these tanks requires no electricity and energy consumption, and the distance between the layers has a vacuum and consists of insulating materials such as perlite (which significantly reduces the transfer of radiant heat), as a result of this, it causes It becomes a very good insulator for heat.

Application of doers

Nowadays, the refrigerant doer is used to store, transfer or supply refrigerant gases according to demand.

The most common use of these tanks is for the economical transportation and storage of gases such as liquid oxygen (LOX), liquid argon (LAr) and liquid nitrogen (LIN) obtained through air separation. It is also used to store liquefied natural gas (LNG) and carbon dioxide (LCO2) at higher temperatures.

- Doors can keep a large amount of gas in liquid form at a relatively low pressure compared to gas cylinders, which increases the level of safety in work environments.

- Doors provide a source of cryogenic fluids that are easily portable.

- Storing gases in a liquid form inside the doors increases productivity in the time and space used.

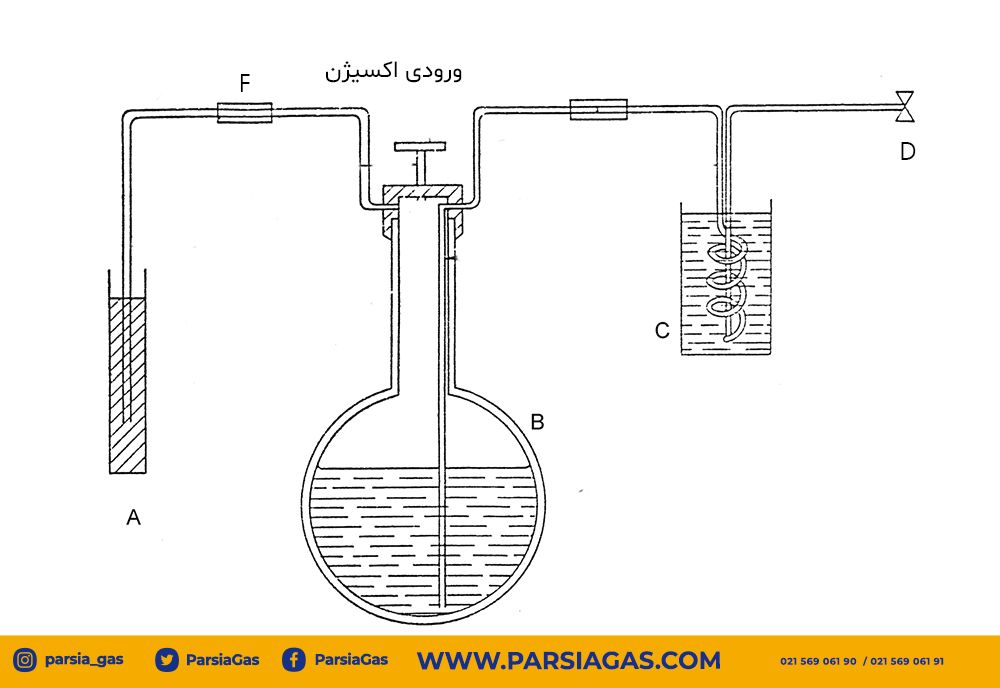

- Doors are also equipped with a vaporizer, having this advantage can somehow convert liquid to gas in the established place without moving. The performance of this converter is based on the difference between the ambient temperature and the liquid temperature, so that the liquid passes through the tubes equipped with aluminum fins and evaporates.

Be sure to read: methods of extracting gases in the air

Leading industries in the use of these tanks

In general, these tanks have many applications and can be used in various and wide fields such as: medical industry, refinery, petrochemical, food industry, transportation, electronics, metallurgy and steel industries. Keep in mind that these cryogenic tanks are designed in different sizes and pressures according to their type and conditions of use.

Security tips for drones:

- Do not under any circumstances place the circles in front of direct sunlight.

- Keep the body of the doers away from sharp objects.

- Place the wheels in a fixed position to prevent it from falling or falling from a height.

- Use suitable means of transportation to move the parts.

- Use standard and suitable equipment (gauge, manometer, valve and tank connections) when using the pumps.