Nitrogen might seem like an ordinary, inert gas, but in the world of science, industry, and medicine, it’s one of the most widely used gases. Over 78% of the air around us consists of nitrogen. However, in its pure form—whether liquid or gaseous— nitrogen serves countless purposes. From cryogenic freezing of biological samples to protecting metals in industrial processes, liquid and gaseous nitrogen play essential roles in modern technology.

But here’s the critical question:

What is liquid nitrogen and how does it differ from its gaseous form?

While this question may appear simple, the answer is layered with technical details that can influence your choice depending on your industrial or medical needs.

This article, a pillar content piece for the ParsiaGas website, dives deep into the differences between liquid and gaseous nitrogen. We’ll explore their properties, applications, benefits, risks, and the key considerations to choose the right type based on your use case.

What is Nitrogen? A Look at the Properties of This Inert Gas

Nitrogen (N₂) is a colorless, odorless, and tasteless gas that makes up about 78% of Earth’s atmosphere. Under standard temperature and pressure (STP), nitrogen exists in gaseous form and is considered inert—meaning it does not readily react with most substances under normal conditions.

Key Physical and Chemical Properties of Nitrogen:

- Boiling Point: −195.8°C

- Molecular Weight: 28 g/mol

- Density at 20°C: 1.25 g/L

- Reactivity: Chemically inert under normal conditions

- Flammability: Non-flammable

Because of its non-reactive nature, nitrogen is widely used in industries that require safety, cooling, or inert environments, such as food processing, pharmaceuticals, metallurgy, and electronics.

What is Liquid Nitrogen and How is it Produced?

Liquid nitrogen (LN₂) is simply nitrogen gas that has been cooled and pressurized to the point that it condenses into a liquid. This transformation requires extremely low temperatures, typically below −196°C.

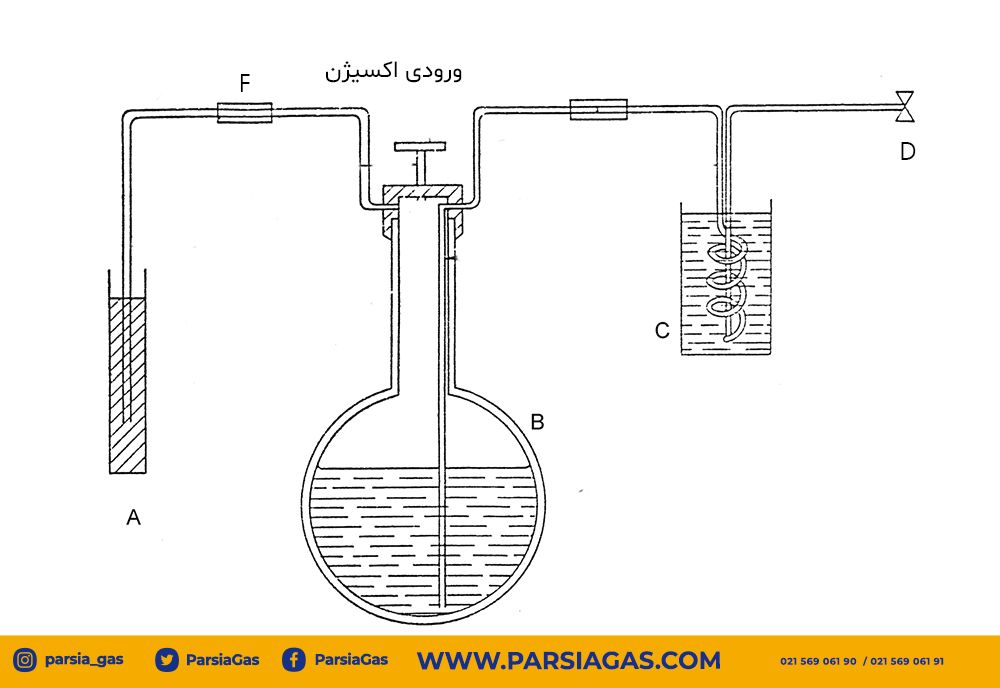

How is Liquid Nitrogen Made?

- Fractional Distillation of Air:

Nitrogen is separated from atmospheric air using a cryogenic distillation process. The air is compressed, cooled, and distilled based on different boiling points of gases. - Cryogenic Cooling:

After separation, nitrogen gas is cooled using specialized refrigeration systems until it becomes a liquid. - Storage:

Liquid nitrogen is stored in vacuum-insulated containers called Dewars or cryogenic tanks to prevent rapid evaporation.

The Difference Between Liquid and Gaseous Nitrogen

While both forms are chemically the same (N₂), their physical states, storage methods, and use cases differ significantly. Here’s a comparison:

| Property | Gaseous Nitrogen | Liquid Nitrogen |

|---|---|---|

| State | Gas | Liquid |

| Temperature | Room temperature | −196°C |

| Density | ~1.25 g/L | ~808 kg/m³ |

| Volume Ratio | 1:1 | 1 liter = ~700 liters of gas |

| Storage | High-pressure cylinders | Cryogenic tanks (Dewar) |

| Safety Concerns | Pressure-related risks | Frostbite, suffocation |

| Best Uses | Purging, pressurizing, inert environments | Cryogenic freezing, biological preservation |

Choosing between liquid or gaseous nitrogen depends on your specific application, volume needs, and safety considerations.

Applications of Liquid Nitrogen in Industry and Technology

Thanks to its extremely low temperature and inert nature, liquid nitrogen (LN₂) is widely used across many high-tech and critical industries. Its cryogenic capabilities make it ideal for processes requiring rapid freezing or ultra-low temperatures.

1. Food Industry:

- Instant Freezing (IQF): Used to quickly freeze vegetables, seafood, meat, and ready-made meals.

- Preserving Texture and Taste: Rapid freezing prevents large ice crystals, preserving food quality.

- Nitrogen Ice Cream: A popular demonstration of science and taste combined.

2. Pharmaceutical and Biotechnology:

- Cryopreservation: Ideal for storing sperm, eggs, stem cells, and tissues.

- Cooling Laboratory Equipment: Especially for sensitive instruments.

- Biological Sample Transport: Maintains sample integrity over long distances.

3. Metallurgy and Automotive:

- Heat Treatment of Metals

- Cryo-fit Assembly of Engine Components

- Cooling Welding Tools and Machines

4. IT and Electronics:

- Data Center Cooling: For high-performance servers and supercomputers.

- Thermal Testing: Simulating extreme cold conditions for chips and circuits.

5. Education and Research:

- Demonstrations in Physics and Chemistry Labs

- Cryogenic Experiments in Universities

Applications of Gaseous Nitrogen

Gaseous nitrogen, due to its inert and non-reactive properties, plays a vital role in various industrial processes where oxygen must be eliminated or a protective atmosphere is needed.

1. Pipeline Purging and Cleaning:

Used to flush oxygen, moisture, or volatile compounds from pipelines in oil, gas, and chemical plants.

2. Pressurization:

Applied to pressurize systems and test for leak detection in manufacturing and infrastructure.

3. Protective Atmosphere:

- In welding, to prevent oxidation during metalwork.

- In packaging food, to extend shelf life and prevent microbial growth.

4. Explosion Prevention:

Replaces oxygen in combustible environments to reduce fire and explosion risks.

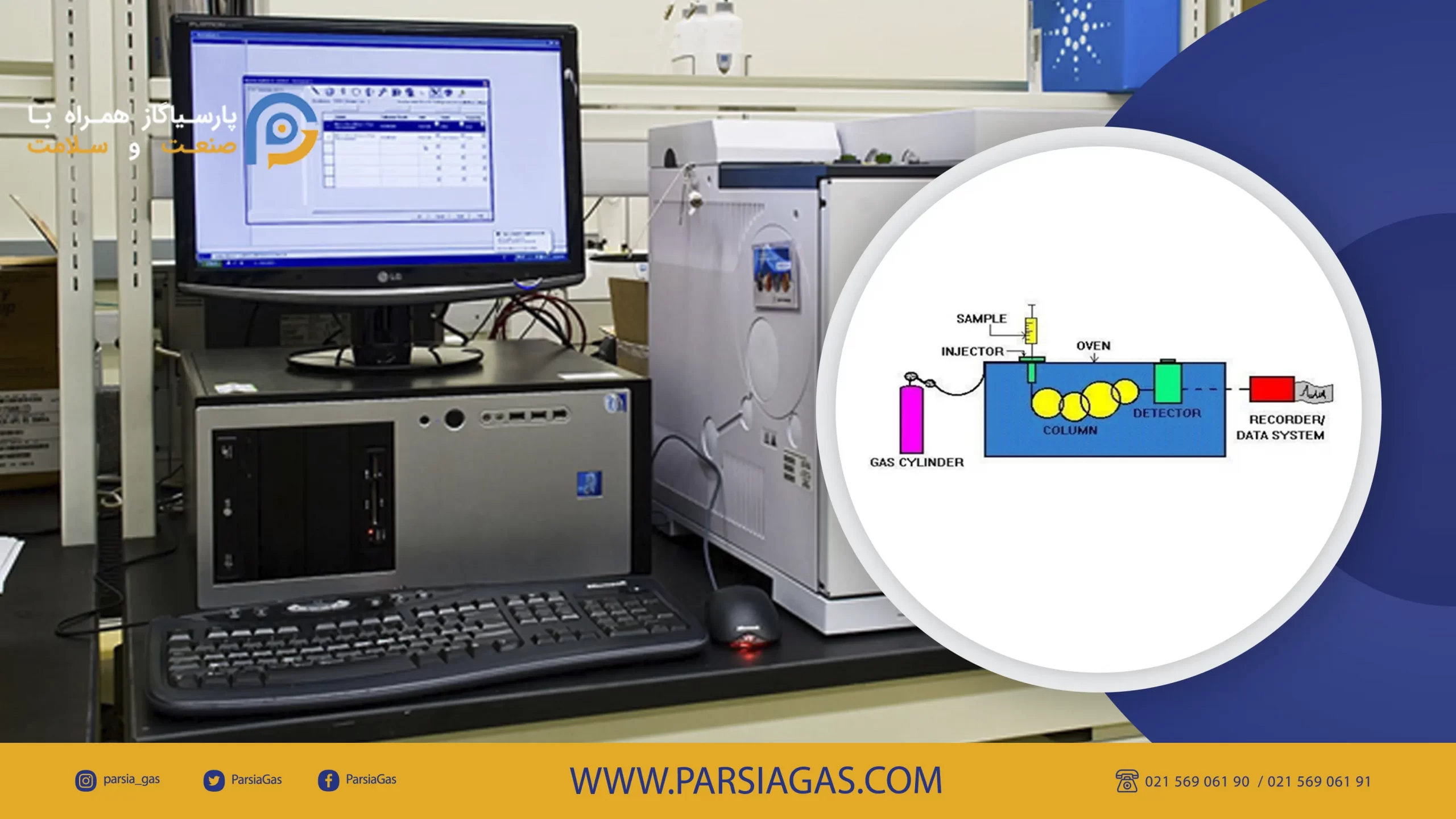

5. Laboratory Use:

- Used as carrier gas in chromatography (GC) and other analytical devices.

- For drying equipment and samples without contamination.

Nitrogen in Medicine: From Cryotherapy to Sample Storage

Liquid Nitrogen:

- Cryotherapy: Treats skin conditions like warts and cancerous lesions using extreme cold.

- Sample Preservation: Safely stores sperm, eggs, stem cells, and biological tissue.

- Cryosurgery: Freezing and destroying abnormal cells in medical procedures.

Gaseous Nitrogen:

- Used in sterile environments in medical labs.

- Carrier gas for precise analysis in medical instruments.

- Sometimes used to dry instruments and containers safely.

Pros and Cons of Liquid vs. Gaseous Nitrogen

| Feature | Liquid Nitrogen | Gaseous Nitrogen |

|---|---|---|

| Volume Efficiency | More gas per liter | Lower efficiency |

| Cooling Power | Excellent | Weak |

| Storage | Requires special cryogenic tanks | Stored in gas cylinders |

| Cost of Equipment | Higher | Lower |

| Ease of Handling | Complex and requires training | Easier and safer |

| Best Use Cases | Freezing, preservation | Purging, pressure testing |

Safety Guidelines for Handling, Storing, and Using Liquid Nitrogen

Due to its extreme cold and potential for oxygen displacement, liquid nitrogen must be handled with care. Without proper safety protocols, it can cause severe cold burns, pressure build-up, or asphyxiation.

1. Frostbite and Cold Burns:

- Always wear cryogenic gloves, protective goggles, and long sleeves.

- Never allow skin contact with liquid nitrogen or surfaces cooled by it.

- Use only approved containers for storage.

2. Pressure Risks:

- Liquid nitrogen rapidly evaporates into gas, increasing pressure in closed spaces.

- Always use Dewars with pressure relief valves.

- Do not seal containers tightly; allow gas to escape safely.

3. Oxygen Displacement and Suffocation:

- In enclosed areas, evaporating nitrogen can displace oxygen.

- Ensure adequate ventilation and install oxygen sensors.

- Train all personnel in safety procedures and emergency response.

Essential Equipment for Using Liquid and Gaseous Nitrogen

For Liquid Nitrogen:

- Dewar Flask or Cryogenic Tank – Double-walled and vacuum-insulated containers

- Cryogenic Gloves and Face Shield – For protection against cold burns

- Pressure Relief Valve – To prevent over-pressurization

- Trolleys or Carts – For safe transport of large Dewars

For Gaseous Nitrogen:

- High-pressure Cylinders (Steel or Aluminum)

- Regulators and Pressure Gauges – To control gas flow

- Flexible Hoses – Rated for nitrogen pressure

- Cylinder Trolley – For moving gas bottles safely

How to Choose Between Liquid and Gaseous Nitrogen

Your choice depends on:

| Requirement | Best Option |

|---|---|

| High volume storage in limited space | Liquid Nitrogen |

| Safe and easy handling | Gaseous Nitrogen |

| Cryogenic freezing | Liquid Nitrogen |

| Line purging or pressurization | Gaseous Nitrogen |

| Biological sample preservation | Liquid Nitrogen |

Always assess safety, cost, application type, and available infrastructure before making a decision.

Market Insights & Conclusion

The global demand for both forms of nitrogen is growing, especially in biotech, pharma, food, and aerospace sectors. Liquid nitrogen leads in cryogenic and medical applications, while gaseous nitrogen dominates industrial use.

Final Tip:

Use liquid nitrogen if your application requires ultra-cold conditions. Choose gaseous nitrogen for everyday industrial purposes.

FAQs:

1. Is liquid nitrogen dangerous?

Yes, if misused. It can cause frostbite and suffocation if proper precautions aren’t taken.

2. How long can I store liquid nitrogen?

Depending on the container type, it can last from a few days to weeks.

3. Can liquid nitrogen turn back into gas?

Yes, at room temperature it evaporates rapidly.

4. Where is gaseous nitrogen commonly used?

In welding, packaging, pressure testing, and laboratory processes.

5. Can I buy nitrogen from ParsiaGas?

Yes. ParsiaGas supplies both forms of nitrogen with technical support and delivery.