Use of nitrogen, argon and oxygen gas in metallurgical engineering

Industrial gases used in mining are used during the processing of minerals and the use of gases to process minerals and metals.

In fact, this part of the extraction process is called metallurgy, which happens with the help of industrial gases. Metallurgy is the process used when extracting metals in their pure form. That is, it is a method used to purify metals and convert them into alloys. For example, sterling silver is made from a combination of silver and copper (sterling silver means 92.5% of its weight is pure silver and 7.5% of its weight is copper) or brass is made from a combination of copper and zinc. will be

High-consumption gases used in the steel and metal industry; They are: oxygen, nitrogen and argon. In this article, we will go a little deeper into how these gases are used in industry and their role in metallurgy.

Oxygen in the steel industry

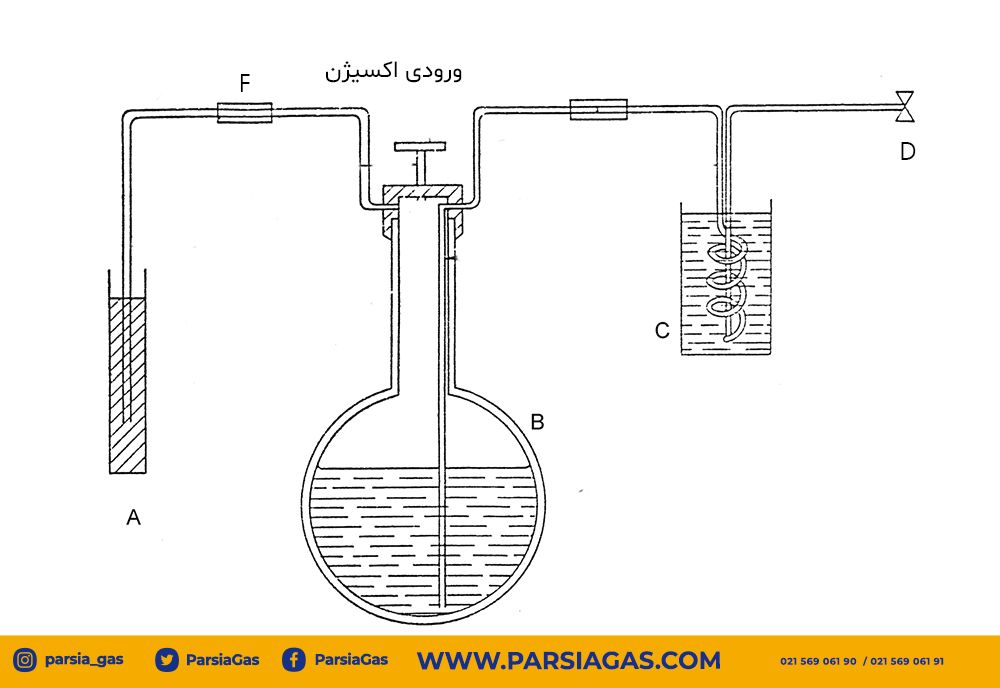

In the steel industry, oxygen is a major component of the basic oxygen process (BOP) and this process takes place in a basic oxygen furnace (BOF). This process involves blowing high-purity oxygen into a furnace filled with molten iron and other waste to turn it into steel.

In fact, it is oxygen that causes a reaction that releases heat and oxidizes impurities such as carbon, for example, oxygen is introduced into the molten bath at an extremely high rate, and this process takes about 20 minutes. (Of course, this time can be different.) This process is to reduce the amount of carbon in steel, and the result is the transformation of hot metal into liquid steel with low carbon content. Other impurities that are found in abundance in the steelmaking process are sulfur and phosphorus.

But sulfur and phosphorus are usually removed by transferring them to the phase rich in calcium oxide with the help of a basic oxygen furnace. After the impurities are removed, the molten steel is poured into the mold to cool, and ferroalloys are added to improve the properties of the steel, such as strength and corrosion resistance.

Nitrogen in the steel industry

Nitrogen is commonly used in metalworking annealing process. Nitrogen annealing means reducing the hardness of the metal and increasing the ductility through heat treatment. In fact, if you want to work with a metal that does not crack under pressure and is easily formed without using additional heat, nitrogen annealing will be an important process (for example, in cold work). .)

Nitrogen, as an inert gas, is used to create an inert atmosphere inside the furnace during the heating and cooling process. Since oxygen blasts are used in furnaces to cause oxidation and chemical reactions, nitrogen has become a key gas to neutralize the environment. Before the actual annealing process, however, nitrogen is used to remove any hazards in the atmosphere that could potentially create an unstable or combustible environment.

Argon in the steel industry

- Decarbonization

- decrease

- desulfurization