Compressed air quality measurement

By means of the compressed air quality test, it is possible to check the purity of the air used in industrial processes, as well as ensure the absence of pollution and impurities that may damage the equipment or the quality of the final product.

Using low quality compressed air can have negative effects on performance depending on where it is used; The use of low-quality compressed air can damage the production results and the health of employees, cause damage and ultimately increase the cost.

What is meant by compressed air pollutants?

Compressed Air and Gas Institute (CAGI) has introduced 10 types of compressed air pollutants.

These pollutants generally come from three different sources, which we will discuss further.

- Pollutants that have been drawn into the air system from the surrounding environment through the air compressor inlet; Ingested pollutants appear in the form of water vapor, hydrocarbon vapors, natural particles, and airborne particles.

- As a result of the mechanical compression process, impurities or pollutants may be produced and enter the air system; These pollutants may be compressor lubricants, wear particles, or vaporized lubricants.

- Presence of internal contamination in the compressed air system; Piping distribution and air storage tanks, which are more common in older systems, contain contaminants in the form of rust, pipe scale, mineral deposits, and bacteria.

International Organization for Standardization (ISO)

The International Organization for Standardization (ISO) is a global network that brings together experts and professionals to provide solutions to global challenges by sharing world-class knowledge and to develop international standards related to the market.

Standards created by the International Organization for Standardization ensure quality, safety and efficiency by defining specific specifications for products, services and systems at the global level.

There are common international standards through which you can check the amount of compressed air and find out how it exists.

International standards are also used to continuously monitor compressed air and check its quality.

Three standards are used for quality measurement of compressed air:

- ISO 8573 Series

- ISO 12500 Series

- ISO 7183

When measuring the quality of compressed air, the type of standard and purity class selected for each pollutant should be specified.

Choosing ISO 8573_1 as a basis for monitoring and quality measurement of compressed air is the best choice; Because it provides a common language that everyone can use and refer to.

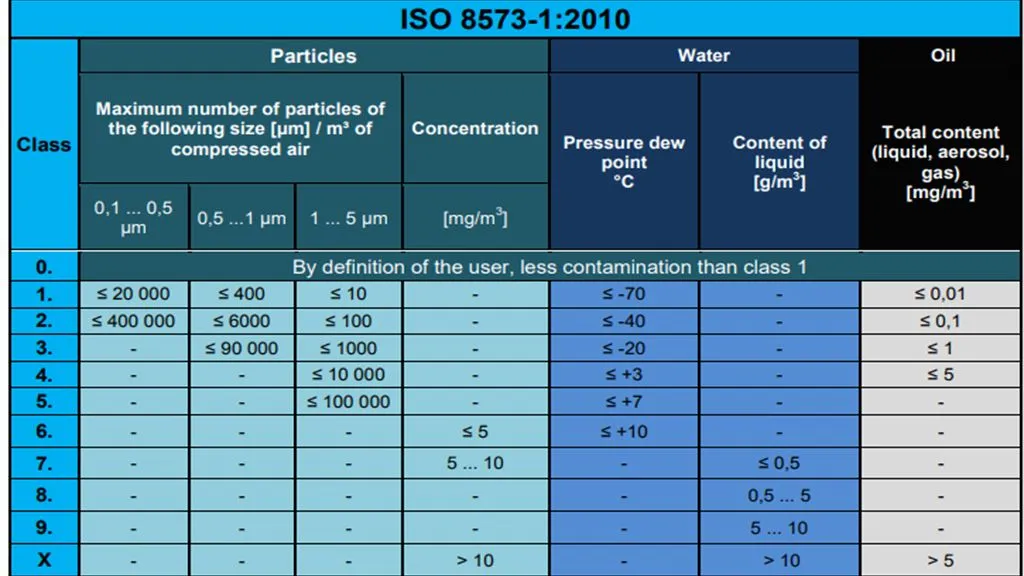

The table below shows the purity classes used by ISO 8573-1 for the qualitative classification of compressed air.

This standard has recently been updated as ISO 8573-1:2010, so it can be used to meet the latest requirements of a wide range of applications as well as the latest developments in compressed air technology.

The purity class can specify the maximum amount of pollutants that may be present in the air stream.

This standard consists of 9 separate parts, part 1 specifies quality requirements for compressed air and parts 2 to 9 specify test methods for a wide range of pollutants.

The ISO 8573-1 standard is divided into three groups based on the type of pollutant: solid particles, water and oil.

In each category, there are different types of classified purity levels; It is very important to know that the lower this number is, the lower the amount of impurities and the cleaner the compressed air.

For different applications of compressed air in different industries, the appropriate grade is specified for consumption.

Purity classes:

Purity classes for each pollutant range from the cleanest “Class 0”, to the most impure “Class 9”; Note that the water category is the only pollutant that uses the full spectrum of these classes.

It is also important to note that the number placed in class 0 has nothing to do with its emission level; In other words, class 0 does not mean that there are no pollutants, class 0 means that there are fewer pollutants than class one.

Be sure to read: Chemical industry

Solid particles (pipe deposits, wear particles and atmospheric dirt):

Eight classes are defined for solid particles; From class 0 to class 7.

Classes 0 to 5 are defined by the number of particles within a specific size range in one cubic meter of compressed air.

Classes 6 and 7 define compressed air that is usually too “impure” to be measured by a particulate counter.

Instead, the mass measurement method is used to determine the amount of pollution in compressed air; To improve the quality of the final product, it is necessary to remove these particles from the compressed air path.

Water (liquid, vapor and aerosol):

There are ten potential classes for water pollution; From class 0 to class 9

Classes 0 to 6 are defined by the dew point of compressed air pressure. Dew point is the pressure level at which moisture in the pipes and storage tanks of a compressed air system begins to condense during operation.

Classes 7 to 9 are used to describe compressed air containing water. When the compressed air pressure dew point is higher than the ambient air temperature, water appears in the distribution and storage pipes.

Be sure to read: methods of extracting gases in the air

Oil (liquid, vapor and aerosol):

The most important parameter of compressed air quality according to the ISO8537_1 standard is the amount of oil.

According to the table and the amount of oil specified for each class, filtration should be done according to the same class.

There are only five classes for oil in the standard, including Class 0, with classes 1 to 4 covering a range from less than 0.01 mg of oil per cubic meter of compressed air, to less than 5 mg per cubic meter.