In what cases is oxygen used in the steel industry?

- blast furnaces

- Basic oxygen furnaces

- electric arc furnaces

- Rotary furnaces

- Heating, cutting and burning of steel

- Overview of steel production

Oxygen in the steel industry

- Blast furnace (BF)

- Basic Oxygen Furnace (BOF)

- Secondary metallurgy

- Continuous Casting (CC)

- Oxygen blowing in steelmaking

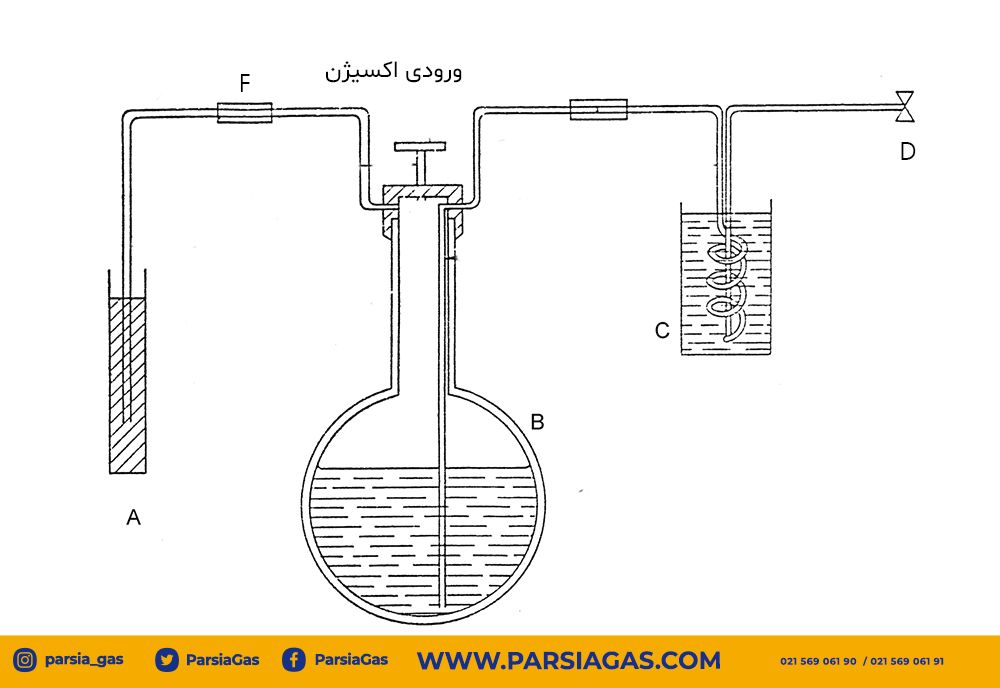

How is oxygen produced?

Until now, the best and least expensive way to produce pure oxygen is to use the ambient air. The procedure for producing pure oxygen is that first the ambient air is taken from the environment with the help of very powerful compressors and then the compressed air is taken into the turbines. These turbines cool the air to a temperature of 190 °C. Cooling the gas causes the initial air to turn into a liquid, then this liquid is introduced into the separating parts to be stored in separate tanks after separation.

The temperature of liquid oxygen is very low and around 183°C. Since liquid oxygen occupies less space, more volume can be produced. Tanks that store separated liquids can store liquids for a long time.

and finally

If you also need high purity oxygen for your steel factory, you can contact us from the contact us section of the site.