Extracting oxygen from the soil of the moon (regolith)

The moon is one of the unacceptable places for humans, it is dry and dusty everywhere and there is no atmosphere to breathe. But it does not mean that there is no oxygen there, in fact, one of the sources available to extract this vital element is regolith.

Soil constituents on the moon

The top surface of soil and rubble is full of oxygen, and now scientists have discovered how to remove the oxygen from them, but this process does not produce waste.

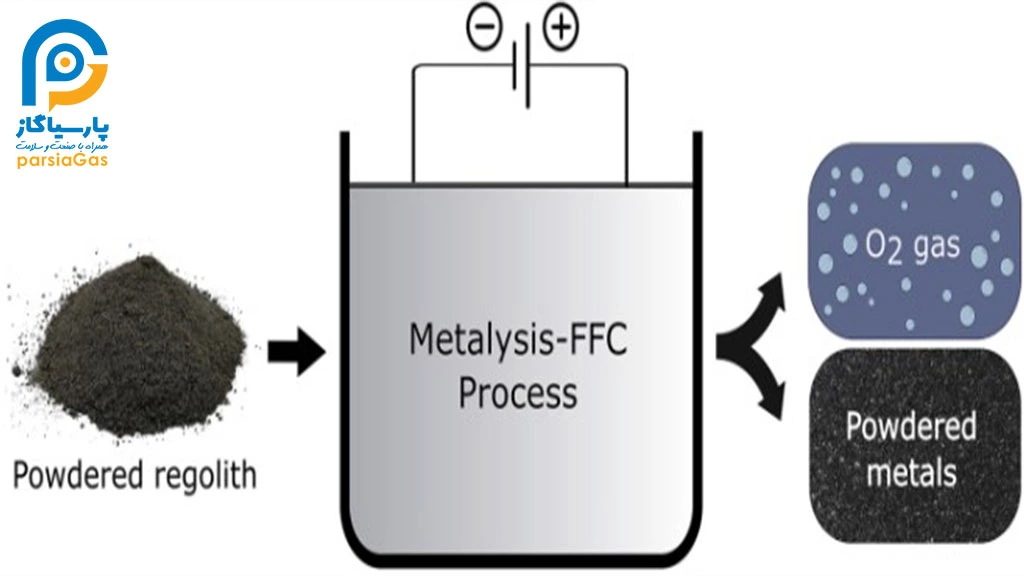

On the one hand, you get a bunch of oxygen and on the other, you get a bunch of metal alloys, both of which will be very useful for building a base or habitation on the moon in the future.

Thanks to samples of lunar soil brought back from previous missions, we know that oxygen is abundant there, in fact oxygen makes up 40 to 45 percent of the lunar soil by weight, and is by far the most abundant component by weight. The elements of the moon are soil.

But there is a big problem; “This oxygen is a very valuable resource, but it exists as a chemical compound in other substances, so it is not available for direct use,” says Scottish chemist Beth Lomax of the University of Glasgow.

Be sure to read: methods of extracting gases in the air

These samples are invaluable for direct testing, and having them means we can recreate them using materials on Earth; This reconstituted soil is called lunar simulant soil, and Lomax and his team used it for their research.

Methods of extracting oxygen from lunar soil

Most of the attempts to extract oxygen from lunar soil were done, such as chemical reduction of iron oxides using hydrogen to produce water, then in the next step the produced water had to be electrolyzed to separate the oxygen from the hydrogen, or a similar process was proposed with methane instead of hydrogen. have been.

But these techniques were low-yield and overly complex, too hot, and required extreme temperatures to melt lunar soil during operation.

Lomax and his colleagues skipped the chemical reduction step and went straight to the electrolysis of lunar soil.

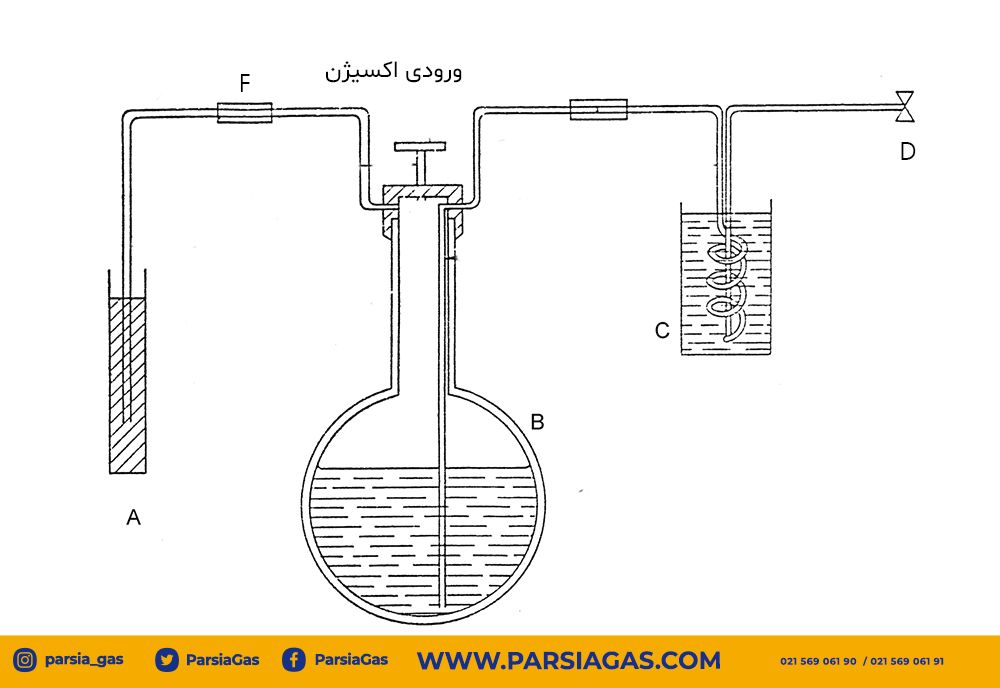

“This processing was done using a method called molten salt electrolysis and is the first example of direct powder-to-powder processing of a lunar soil simulant that can extract almost all of the oxygen,” Lomax explained.

In the alternative methods of extracting oxygen from the moon, which require melting the lunar soil with a temperature of more than 1600 degrees Celsius (2900 Fahrenheit), they have much lower efficiency.

But in the electrolysis method, they first place the moon soil in a mesh basket, then add calcium chloride as an electrolyte and heat the resulting mixture to about 950 degrees Celsius (a temperature that does not melt the moon soil). An electric current is then applied, which extracts this oxygen and transports the salt to the anode, where it can be easily removed.

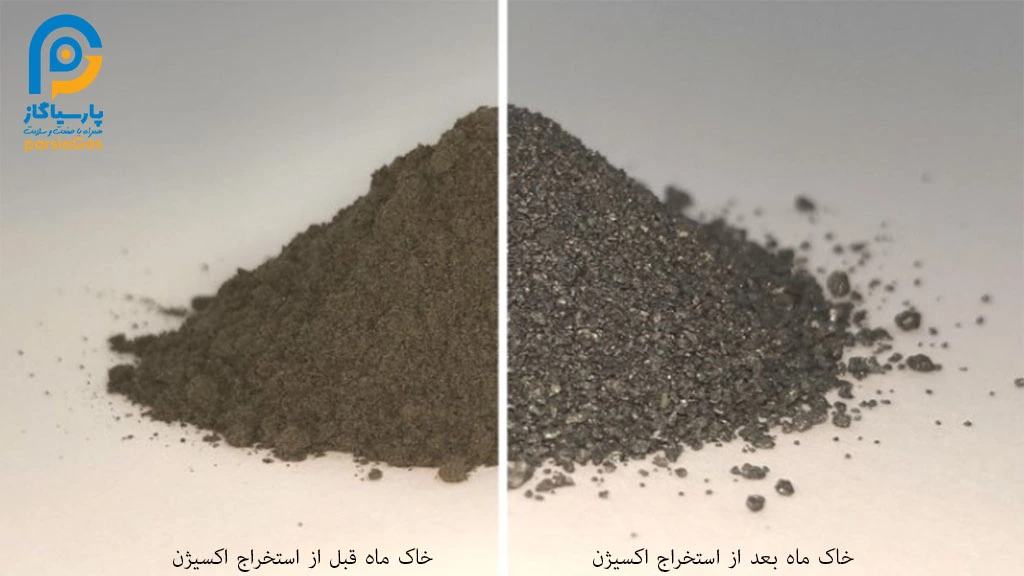

It took about 50 hours to extract 96 percent of the oxygen in the lunar soil sample, but 75 percent of the oxygen was removed in the first 15 hours. Approximately one-third of the total oxygen in the sample is collected as gas and the rest is removed, but this extraction rate is a major improvement over previous techniques; In addition, the remaining metal can also be used.

“This is the first successful demonstration of powder-to-powder processing of a lunar soil simulation that produces metal alloys as products,” the researchers wrote in their paper.

Furthermore, the clear separation of different alloy phases and the apparent reduction of other metallic components introduce an exciting potential for alloy metal separation and refining from unused lunar soil.

There were three main alloying groups in the byproduct, sometimes mixed with small amounts of other metals: iron-aluminum, iron-silicon, and calcium-silicon-aluminum.

The discovery means the method could still be valuable even if it turns out that oxygen can be extracted from ice deposits on the moon.

This process would give lunar inhabitants access to oxygen for fuel and life support, as well as a wide range of metal alloys for on-site production, said James Carpenter, ESA’s lunar strategy officer.

Source: www.sciencealert.com

Be sure to read: The use of gases in the food industry